Biomass Boiler and Material Drying Facility

Ellgia is fully committed to providing solutions that help our customers improve their environmental performance. We have made a significant investment in a biomass boiler and drying facility in order to move waste away from landfill disposal solutions and up the waste hierarchy.

As part of this commitment, Ellgia can manufacture fuel products from its waste processes in the form of Refuse Derived Fuel (RDF) and Solid Recovered Fuel (SRF). These fuels are produced to the highest possible specifications through mechanical processing, physical treatment and material extraction to produce the fuel to highly regulated and monitored standards.

In order to meet the standards required in manufacturing fuel, we have to pay particular attention to the moisture content in the fuel itself which is why we have invested in a biomass boiler and drying facility. This allows the fuel to be conditioned to the optimum moisture content before it is shipped to either Energy From Waste (EFW) plants or is used as direct replacement for fossil fuels in the manufacture of cement.

The biomass boiler is fuelled using clean grade-A waste wood which is recycled from our incoming Commercial and Industrial (C&I) and Construction and Demolition (C&D) waste streams. The wood is extracted from mixed waste via our mechanical extraction and physical treatment processes or collected directly from customers’ sites, it is then shredded and screened to produce a clean and sized material to meet its own set of specification requirements.

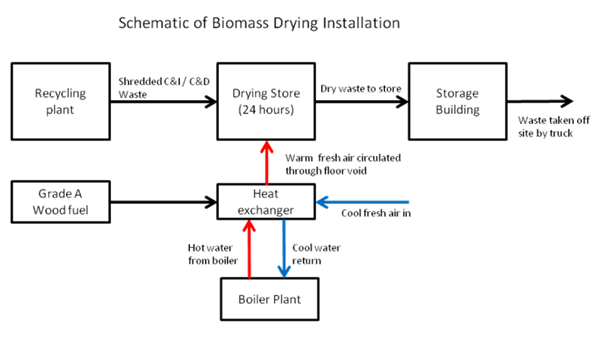

How the process works

At the heart of the facility is an Ariterm 1MW boiler; where the combustion of the woodchip is used to heat fresh air that is then circulated through a specially designed building suitable for drying a range of bulk materials.

Fresh outside air is heated in a heat exchanger by hot water from the closed boiler heating circuit. The hot air is passed via ductwork through a grated floor in the drying building.

The air moves through the shredded material in a single pass and in doing so reduces the moisture content of the material inside.

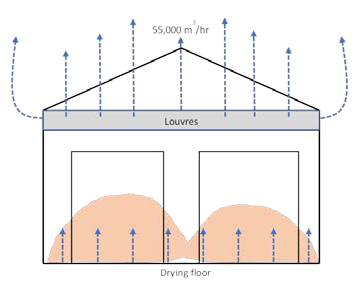

Drying process

The drying floor is designed to pass 55,000 m³/hr of fresh air through the drying store. The air makes a single pass (no recirculation) through the floor of the drying building up through the shredded material and out of the building at a high level.

If you are interested in our services contact us on 01223 322799 or email us on info@ellgia.co.uk

Want to find out more?

A dedicated member of our team is ready to help you.