Processing RDF and SRF Fuel

Ellgia’s investment in turning waste into a resource has led to the long-term supply of both Solid Recovered Fuel (SRF) and Refuse Derived Fuel (RDF waste) to key facilities in the UK producing energy to heat homes across the UK.

Ellgia are committed to providing “zero to landfill” solutions and have invested significantly in turning those waste that cannot be recycled into waste derived fuel products, Ellgia have not only developed processing capability to enable waste to be converted to a useable fuel, but we have also invested in long term UK based offtake partnerships to ensure the movement of materials is kept to an absolute minimum. Our Solid Recovered Fuel (SRF) and Residual Derived Fuel (RDF) is made to the highest specifications to enable us to direct to key facilities to replace existing fossil fuels or to energy recovery facilities to produce electricity supplying heat and power to thousands of homes across the UK.

We have invested heavily in our fully permitted facility in Scunthorpe to establish it as a central hub for waste derived fuel production. The 18 acres facility and its strategic positioning in the East of England and our future expansion plans means it is ideally positioned to deliver on our ambitious growth targets and the rising demand from our customers to move waste up the hierarchy.

Why Refuse Derived Fuel?

Our Refuse Derived Fuel (RDF) production has enabled UK waste producers, who produce more organically contaminated waste materials that are traditionally more difficult to recycle, to transform their unrecyclable waste with historically more traditional landfill disposal routes to a waste derived fuel that is used to produce heat and power to local residents across the UK.

Many general waste streams can be economically and practicably processed to mine for recyclable materials, however what happens to the residual waste element that cannot?

These contaminated streams with higher organic compositions and lower calorific values (CV) means they are ideal feedstock for the production of Refuse Derived Fuel (RDF) which are utilised in technologies designed for these steams such as Energy from Waste (EfW) plants to convert to electricity and useable energy, but how do we transform the waste to fuel?

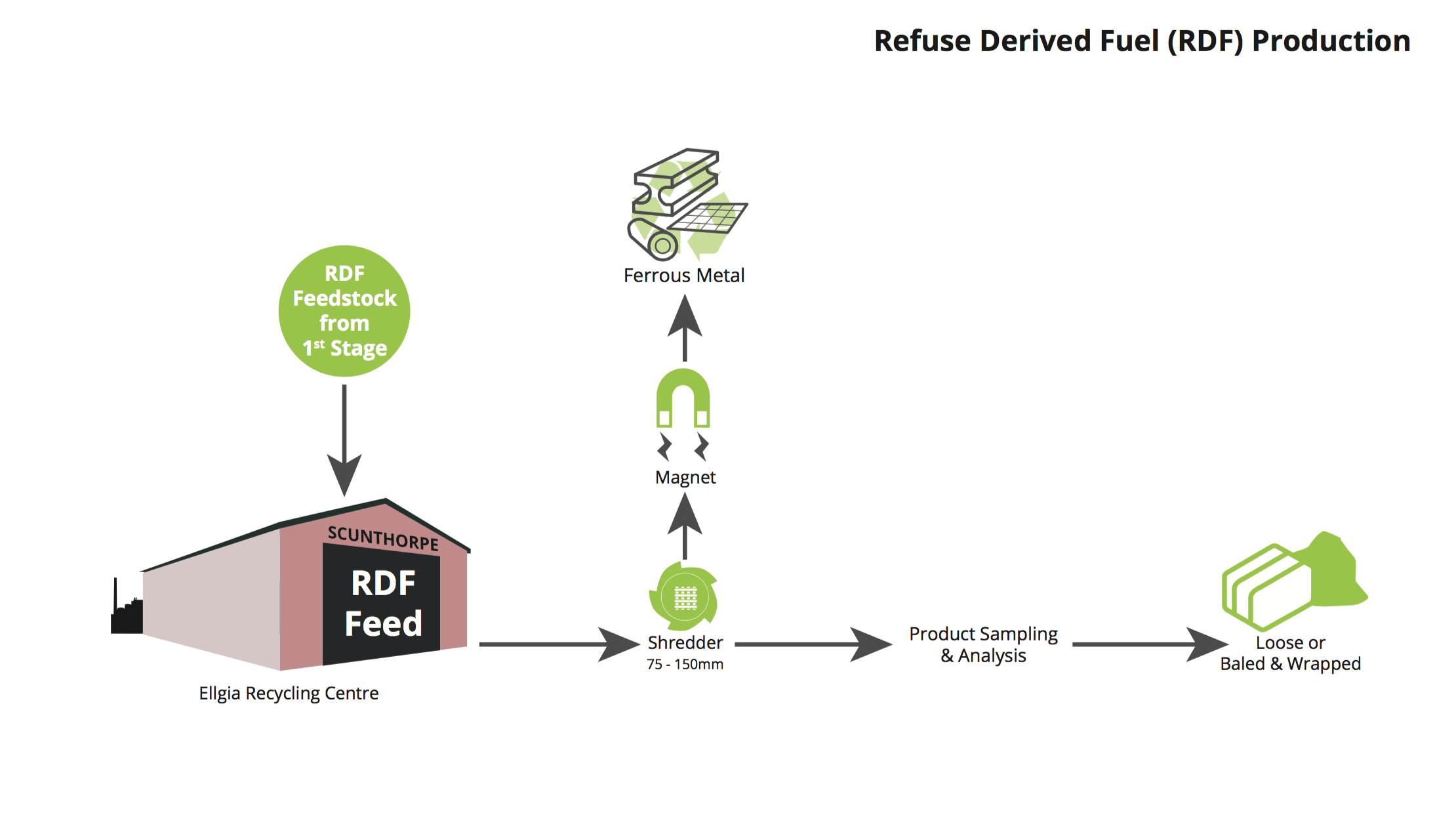

On arrival at our facilities, we start the process by removing any recyclable materials from the stream though several mechanical processing lines which separate the potential recyclable materials. The residual waste element that cannot be reused or recycled is further processed to reduce its particle size and a final filter of the load for any further opportunities to recover further recycling materials.

The material is sampled and assessed to ensure it meets the specifications our offtake partners before being shipped to the required energy recovery facility via our own extensive fleet of Walking Floor artic units.

Ellgia enforce a stringent weekly sampling and external analysis programme to ensure that the RDF we produce meets the highest standards of production and the material acceptance criteria required.

The production of Refuse Derived Fuel (RDF) immediately reduces the need for landfill and enables value to be gained for local residents from the production of green energy .

Solid Recovered Fuel (SRF)

As part of Ellgia’s continued commitment to decarbonisation, moving waste up the hierarchy and offering viable alternatives to traditional manufacturers in their use of fossil fuels Ellgia have continued to invest in other alternative fuel production.

As part of Ellgia’s ongoing investment programme we have continued to challenge ourselves on ways to improve waste processes, enhance recycling performance and continually strive to move waste up the waste hierarchy. ,

There are materials which are difficult to recycle or separate and that do not meet the feedstock requirements to be considered as an RDF fuel feedstock. These materials generally have a higher calorific value, no organic contamination and have a naturally lower moisture level. These properties do not comply with the specifications required to be suitable for the majority of technologies used in energy recovery facilities.

Ellgia has made significant investment in the processing technology to produce a product called Solid Recovered Fuel (SRF).

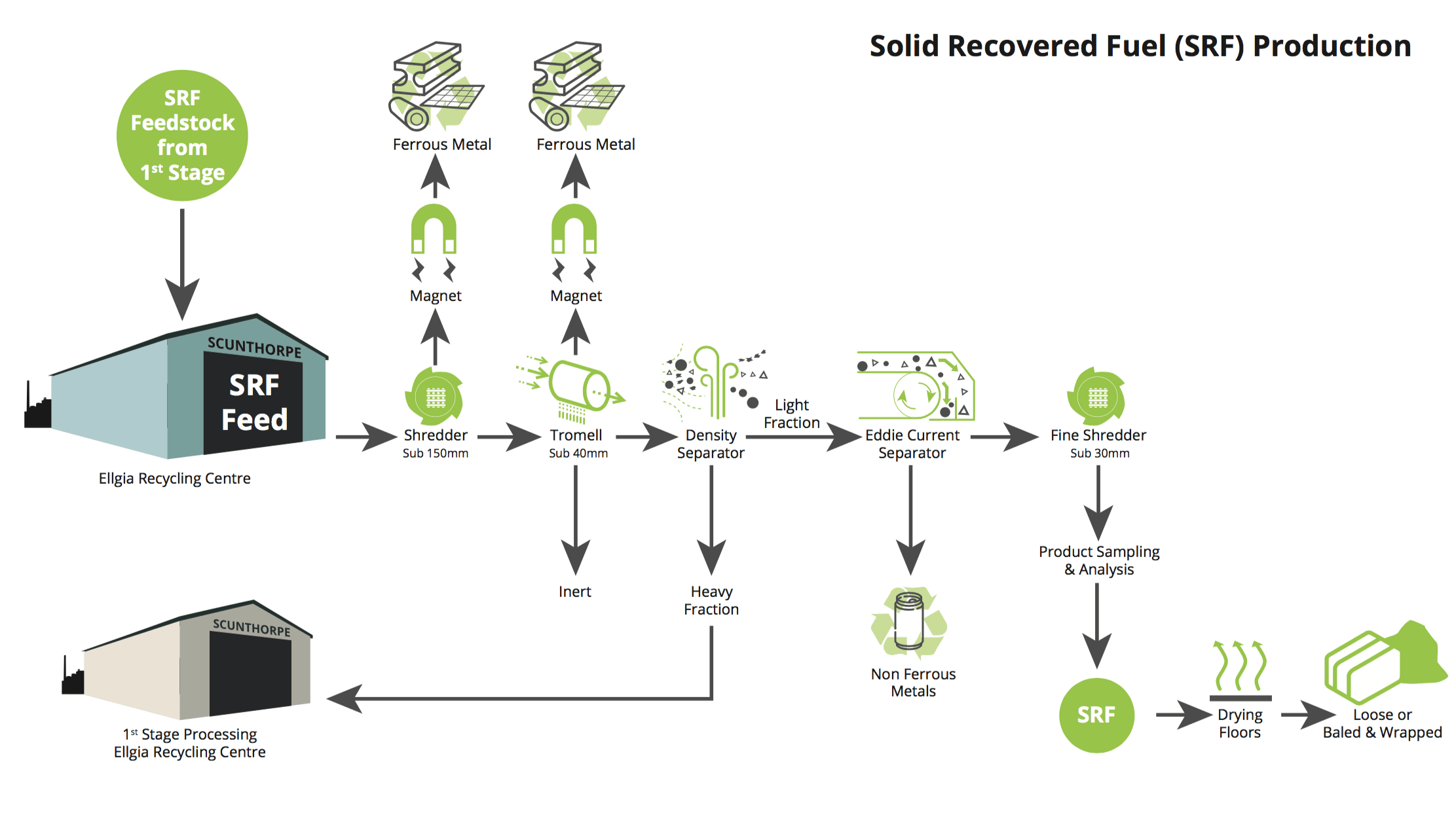

SRF is a waste derived product which meets a waste fuel specification well in excess of those demanded by RDF and requires additional levels of physical treatment, material extraction and management of the final waste composition. This results in a higher quality of fuel that can be utilised in cement kilns and some ERF facilities (energy recovery facilities) to produce power and energy or replace damaging fossil fuels.

The SRF product is tested against a much higher level of acceptance criteria which involves a chemical composition analysis to ensure it can be accepted as a viable replacement for fossil fuels. The SRF product also requires a much smaller final 2D particulate size, a much lower moisture content, a significantly improved calorific value (CV) and a much more stringent control of chemical composition and dust levels. This specification is achieved through Ellgia’s SRF mechanical sorting, separation and shredding process line and is subject to daily sampling and product analysis.

Ellgia has also invested significantly in a biomass boiler, which treats Grade A wood which is accumulated as part of the recycling processing lines, into hot air which is blown through the SRF product to manage moisture levels within the fuel product.

The material is sampled and assessed to ensure it meets the stringent specifications our offtake partners before being shipped to the appropriate facility via our own extensive fleet of Walking Floor artic units.

Want to find out more?

A dedicated member of our team is ready to help you.